to explore

Developing technology for the gem and jewellry industry

SSEF Instruments was founded in 2014. It is a subsidiary of the Swiss Gemmological Institute SSEF one of the leading gemmological laboratories in the world.

SSEF founded SSEF Instruments with the purpose of developing, marketing and distributing new instruments for the gem and jewellery industry.

Discover our products

Our mission is to develop instruments that can serve the trade

Diamonds

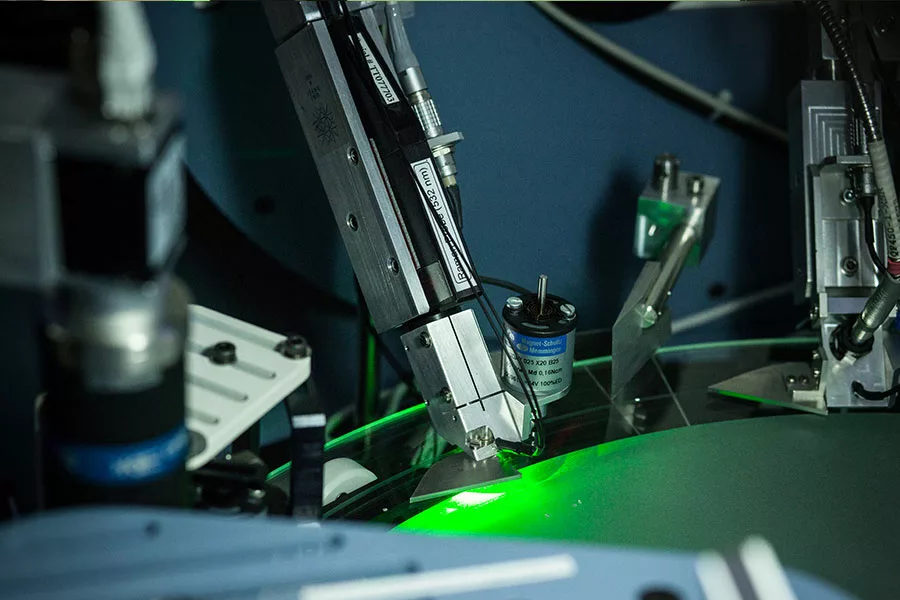

Diamond testing requires enduring and consistently high quality standards. This applies as much to lots of small diamonds as it does to large coloured diamonds. SSEF has developed ASDI for the watch and jewellery making industry, a device which can analyse very large quantities of melee diamonds at low cost. The machine uncovers colourless synthetic diamonds, both HPHT and CVD grown, as well as colourless HPHT-treated diamonds.

Coloured Gemstones

Testing of coloured gemstones is increasingly important and demanded as questions of authenticity, treatment and origin arise in the trade. SSEF and SSEF Instruments are developing new instruments for the coloured gemstone industry. An example of that is the UV-Vis mobile spectrometer, a powerful gemmological tool for collecting spectroscopic data helpful for authenticity and origin questions.

Pearls

Pearl testing can be challenging. Our leading position and competence in natural pearl identification is a result of decades-long research on the subject and of our developing some of the most advanced destruction-free technological methods that enable us to test pearls. Tools such as recently developed PearlScan™ technology help users count, document and measure pearl necklaces.